MEASURING OUR WAY TO DIFFERENTIATION

Data is the backbone of differentiated natural gas; it is what truly enables differentiation. In order to accurately measure how much methane is emitted from the production and transport of natural gas and reduce it cost-effectively, advanced measurement technology is crucial. The development of advanced technologies such as aerial surveillance and site-level direct measurement—utilizing continuous monitoring technology—is already providing critical data to help reduce methane emissions throughout the natural gas value chain.

In February, the International Energy Agency published its 2023 Global Methane Tracker. This report indicates that global oil and gas production emitted 135 million tons of methane in 2022 and even this large number may represent an undercount. Most U.S. companies only use methane leak detection and repair (LDAR) as required by federal and state law and nothing more. New advanced measurement technologies, however, can now provide a full picture of a site’s emissions. Some operators utilizing these rapidly advancing technologies are leveraging the data to identify emissions mitigation opportunities. Once detected, methane leaks in the oil and gas sector can often be remediated using simple engineering solutions, such as replacing a valve or tightening bolts. These practices could potentially lead to significant field-wide methane emissions reductions.

The next frontier in emissions measurement is quantification, the actual measurement of site-level emissions. This is challenging because there are so many potential emission sources across the natural gas value chain. How can companies measure these potential sources in an accurate, timely, and cost-effective way? Traditional approaches for LDAR have typically involved hand-held optical gas imaging (OGI) cameras, which can only be used when trained personnel visit a well pad, to provide a visualization of methane leaks at various resolutions and distances. However, the shift from periodic LDAR to more accurate measurements will require more sophisticated sensors to detect and quantify intermittent sources of methane emissions.

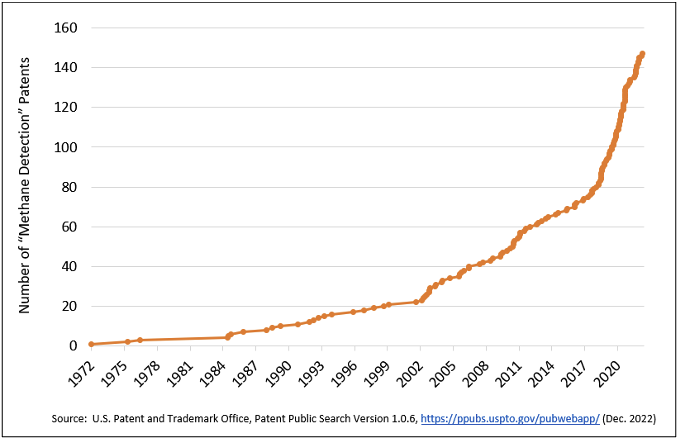

New technologies, including hand-held and drone-based OGI, manned aircraft, satellite, and stationary methane sensors, substantially expanded the capabilities and availability of direct measurement and continuous monitoring services. In recent years, the number of sensor technologies grew rapidly and they now promise to enable increasingly cost-effective methane solutions. The chart below illustrates that the number of patents for methane detection devices has doubled since the Environmental Protection Agency (EPA) promulgated methane rules in 2016. These new technologies, when used in an integrated fashion, serve to strengthen the accuracy of methane emission calculations.

While much of the technology needed to scale differentiated gas already exists, it is important to encourage continued investment in the development of new methane measurement technologies and other innovations that may make these technologies more efficient and accessible. For this reason, the Differentiated Gas Coordinating Council (DGCC) supports a technology-neutral approach to federal and state policies—laws and regulations should not dictate which technologies can be utilized. Instead, these policies should focus on quantifiable outcomes, specifically a robust understanding of actual, on-the-ground emissions. This allows for the quick identification and remediation of emission sources and will encourage the adoption of more efficient and accurate technology as it is created. The DGCC recently provided comments on proposed regulations from EPA and the Bureau of Land Management advocating for such an approach.

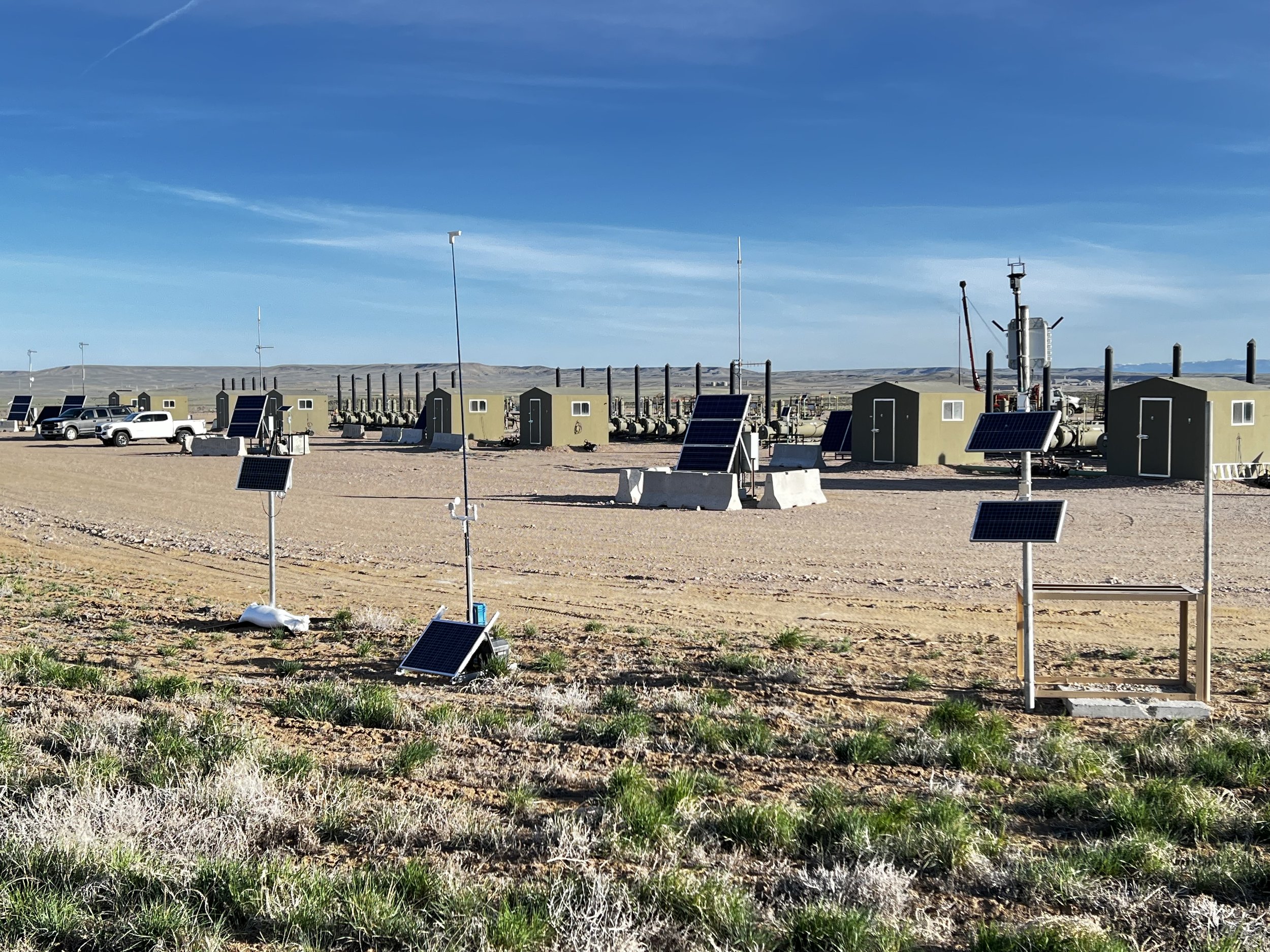

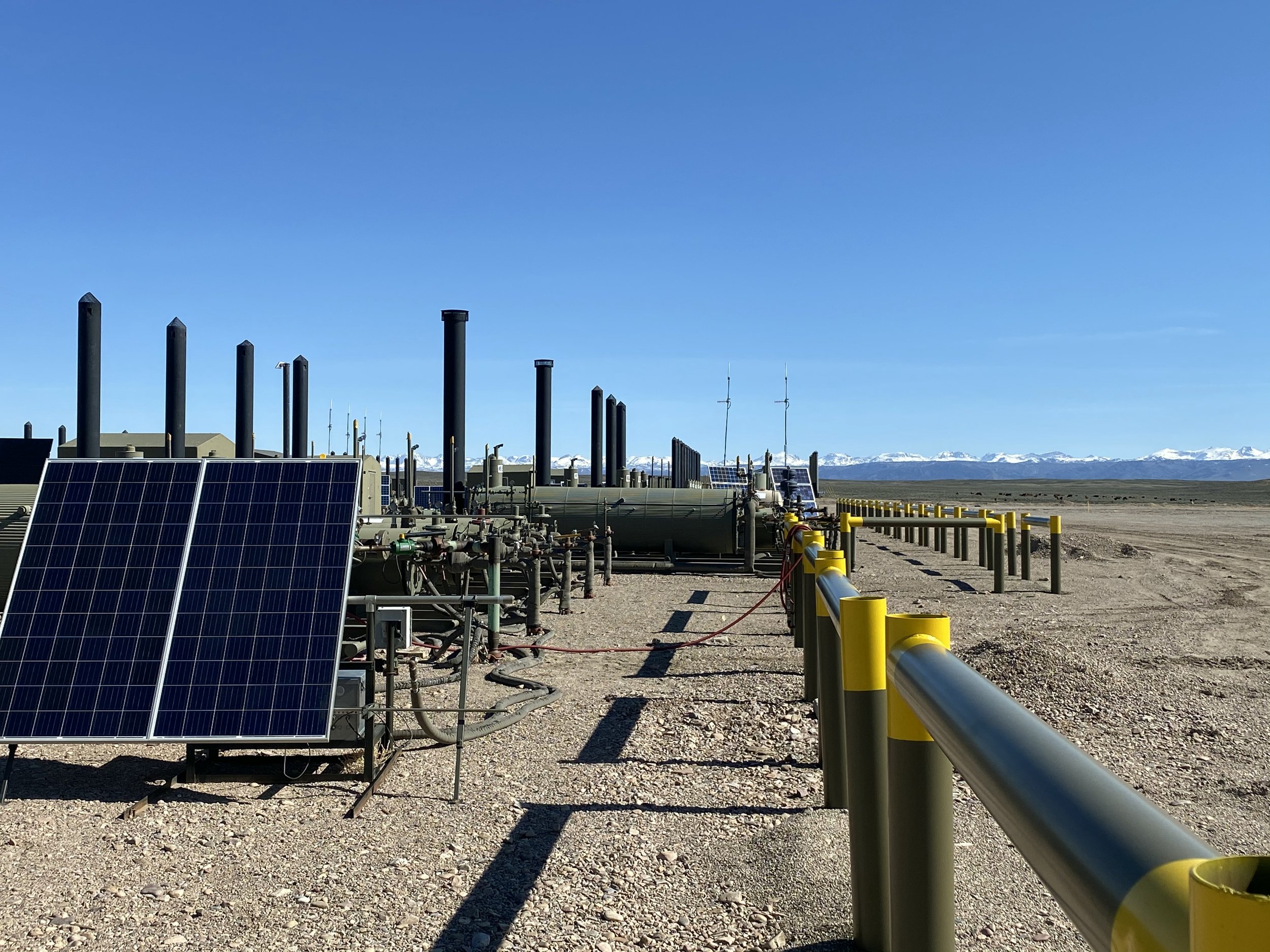

Continuous Emissions Monitoring (CEM) technologies in field testing sites in Pinedale, Wyoming, courtesy of PureWest Energy.

Experts from industry and academia roundly agree that the current methods by which the United States and the international community collect and calculate data on methane emissions are inaccurate. Traditionally, the data used by federal agencies and international organizations, such as the EPA’s Greenhouse Gas Reporting Program, are estimates collected using a spreadsheet-driven approach. The aggregate amount of emissions is based on estimates of gas-loss rates per unit of activity. More specifically, emissions are calculated via formula, aggregating estimates based on equipment counts, not through direct observations. Using this spreadsheet-driven approach, estimates of methane emissions per operator and country vary each year. This is not necessarily due to a physical change in emission levels, but a change in the method of calculation, demonstrating the inaccuracy of this approach.

New methane detection practices use remote sensing via satellite, aircraft, or stationary sensors to determine the concentration of methane in the atmosphere in a given area. With the proliferation of these technologies, our ability to differentiate gas products has, and will continue to, become more accurate and trustworthy.

Leadership for Measurement Technology

The drive for measurement technology organization and coordination is well underway, with several initiatives in academia, industry, and non-governmental organizations taking the lead.

The Energy Emissions Modeling and Data Lab (EEMDL), an initiative of the University of Texas at Austin, Colorado State University, and the Colorado School of Mines, works to develop transparent models and datasets for accurate greenhouse gas emissions accounting across global oil and gas supply chains. EEMDL manages and maintains the Fugitive Emissions Abatement Simulation Toolkit, often referred to simply as “FEAST,” which helps operators and regulators compare a variety of LDAR program configurations, such as continuous monitoring systems and hybrid aerial and ground surveys to develop cost-effective mitigation protocols.

The Oil & Gas Methane Partnership 2.0 (OGMP 2.0) is a multi-stakeholder initiative launched by the United Nations Environment Programme (UNEP) and UNEP’s Climate and Clean Air Coalition. The OGMP 2.0 is a comprehensive, measurement-based reporting framework for the oil and gas industry that improves the accuracy and transparency of methane emissions reporting in the sector.

The Payne Institute, through its Responsible Gas Initiative, convenes a group of academic leaders to discuss and determine the key environmental criteria and measurement standards necessary to build and sustain confidence in differentiating natural gas and its various environmental attributes. The Institute also seeks to provide clear and transparent information to buyers and other interested parties.

GTI Energy’s Methane Emission Measurement and Verification Initiative, Veritas, is a set of protocols designed to assemble methane emissions inventories that are verified by direct field measurements. These protocols are standardized, science-based, technology-neutral, and measurement-informed.